Beamicon2-Basic

CNC control for builders who want reliability.

PC software + Ethernet controller for milling, routing, plasma and special machines. No dedicated “real-time PC” required.

PC software + Ethernet controller for milling, routing, plasma and special machines. No dedicated “real-time PC” required.

| Feature | Basic-Version | Vollversion |

|---|---|---|

| • Ethernet connection | X | X |

| • fully automatic detection of the hardware no dedicated network connection required, can be integrated in the network | ||

| • max. 9 axes interpolated | 4 | X |

| • max. 1600kHz step frequency | X | X |

| • System for Windows (XP-Win11) | X | X |

| • Graphic 3D display of the tool path | X | X |

| • All machine settings can be imported/exported, also partial quantities | X | X |

| • Processing of DIN-ISO G-code | X | X |

| • Import of DXF/HPGL | X | X |

| • Import of graphics/images for engraving | X | X |

| • Optimised path preview with jerk limitation, adjustable transverse acceleration and S-shaped ramps | X | X |

| • Adaptation of speed to the course of the curve | X | X |

| • Improved surface quality through reduced jitter when interpolating multiple axes | ||

| • Tool management with radius and length correction | - | X |

| • Unlimited number of tools | 1 | X |

| • Extensive macro language with loops and variables | X | X |

| • Extensive calculations such as ASIN, ACOS, TAN, ATAN, ROUND, EXP, LOG possible in G-code | X | X |

| • Preview of machine running time | X | X |

| • Feed and spindle override 0-150% while machining is in progress | X | X |

| • Adjustable jog speeds | X | X |

| • Offset management (G53, G54-G59, parking, temporary offset) | X | X |

| • Automatic rotary axis for tangential knives | X | X |

| • Automatic drum engraving | X | X |

| • Speed output PWM/0..10V | X | X |

| • Unlimited number of inputs/outputs (with extension module) | X | X |

| • Dual drives (master/slave) on all axes | X | X |

| • Handwheel with network connection | X | X |

| • Thirdparty handwheels/MPG | +costs | +costs |

| • Images engraving function | X | X |

| • Freely definable hotkeys | X | X |

| • Freely assignable hotkeys to hardware inputs | X | X |

| • Built-in update function | X | X |

| • support request at the touch of a button | - | X |

| • extensive log functions | X | X |

| • Built-in user administration | - | X |

| • Open-GL optimisation | X | X |

| • MDI line, multiple commands | X | X |

| • Styrofoam wire cutting(XY+UV axes) | X | X |

| • backlash compensation | X | X |

| • Short-circuit proof outputs | X | X |

| • Range monitoring of the axes (soft limit) | X | X |

| • Integrated G-code editor with syntax highlighting | X | X |

| • Camera support for up to 10 cameras | +costs | +costs |

| • Minimum quantity lubrication MMS direction-controlled (via 4 valves) | X | X |

| • Programmable maintenance interval | - | X |

| • Central lubrication supported (interval etc.) | - | X |

| • Freely programmable macros | - | X |

| • Freely programmable cycles | - | X | v

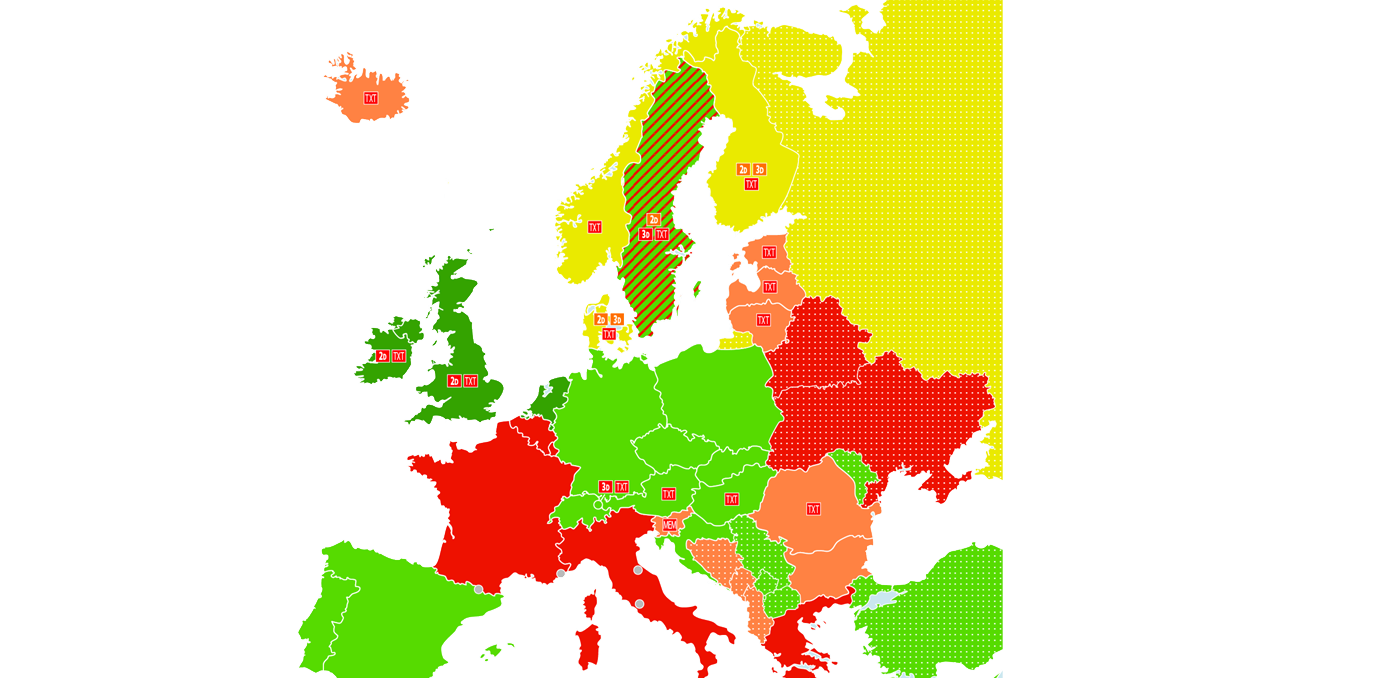

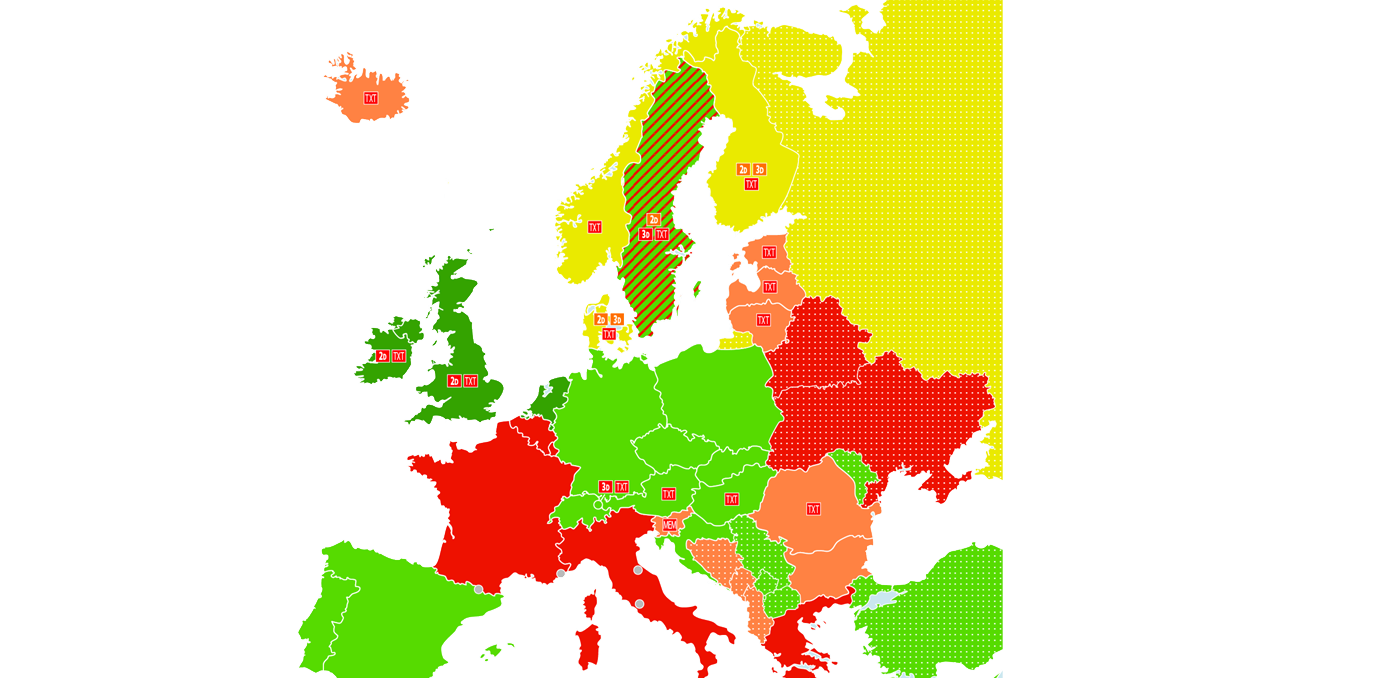

| • Support for many languages | X | X |

| • Reference switch position freely selectable (start/end/centre) | X | X |

| • CV mode extensively configurable (chord error, acceleration) | X | X |

| • Tools can limit the maximum speed (e.g. edge finder) | - | X |

| • Built-in digital logic | - | X |

| • Built-in PLC | - | X |

| • Redundant safety circuit | - | X |

| • Safety door with set-up mode | - | X |

| • Definition of forbidden areas, e.g. tool changer in the working area | - | X |

| • Startup and stop macros to perform specific tasks | - | X |

| • Automatic loading of the last programme (can be switched off) | - | X |

| • Monitoring of directories and automatic loading | - | X |

| • Convertible from mm to inch | X | X |

| • Macros for height measurement and centre finder integrated | X | X |